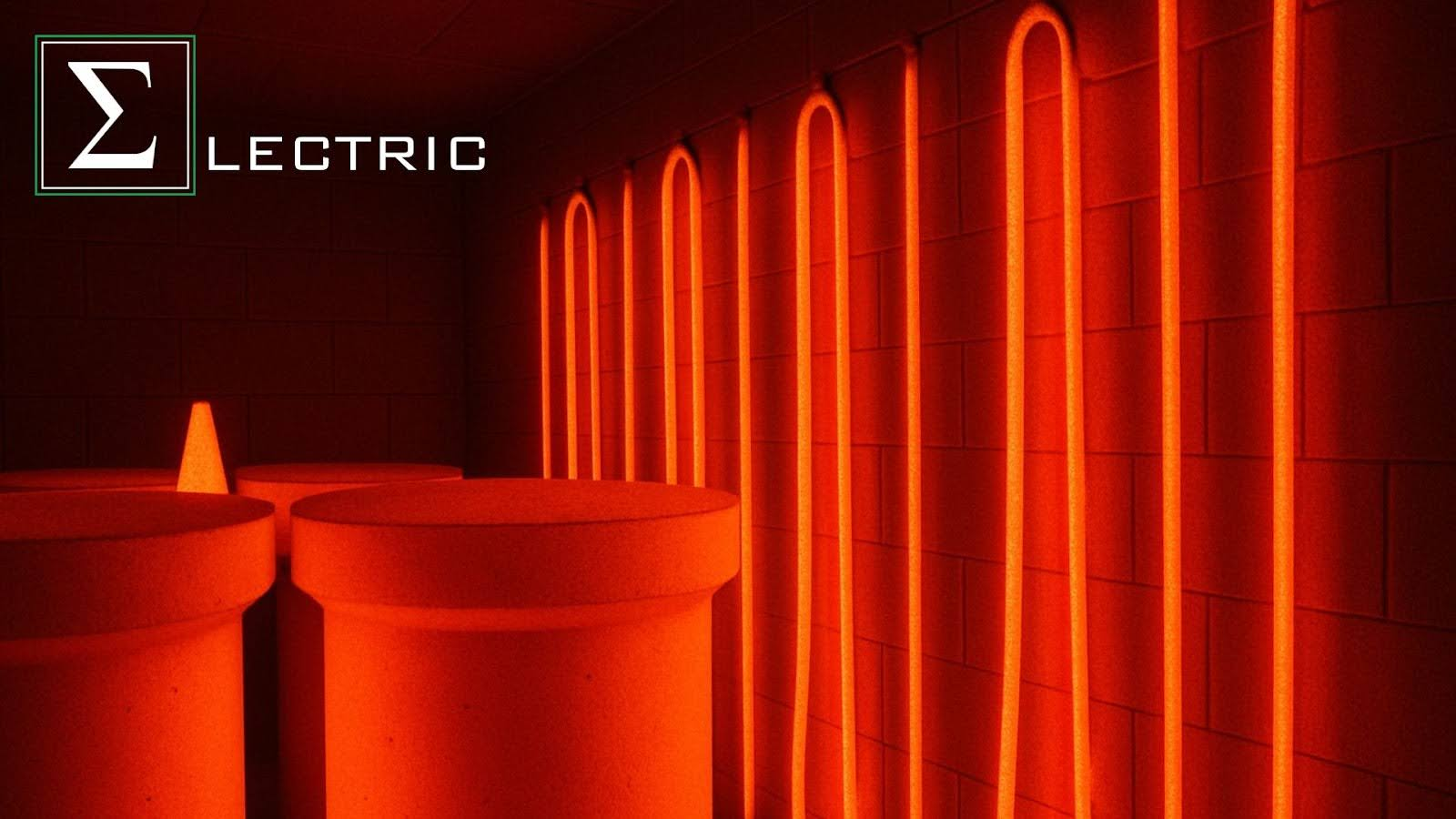

A New Era Begins: Our Electric Furnace Is Now Live

The Furnace of the Future Is Here

We’re proud to announce that our next-generation electric furnace is now fully installed and operational at our Plovdiv facility. With firing capability up to 1750°C, it stands as a landmark achievement in the refractory industry — combining high-performance sintering with a near-zero carbon footprint.

Our Testing Suite: Ensuring Excellence at Every Step

Why This Matters

This project marks a major step in Sigma Group’s journey toward full sustainability and continuous innovation.

- Drastically reduced CO₂ emissions: Fully electric operation replaces fossil fuels, while our on-site photovoltaic system (340,000 kWh/year) powers the process and saves 180 tons of CO₂ annually.

- Unmatched precision: Digital firing control ensures consistent quality, repeatable performance, and better end results.

- True industry leadership: This is one of the first electric furnaces of its kind for refractory production — a feat many said wasn’t possible. We made it happen.

From Vision to Reality

Reaching this milestone required bold thinking, technical excellence, and unwavering commitment. Designing a high-temperature furnace that could run electrically while maintaining stability and throughput was no small task. Our engineering team pushed boundaries — and proved that sustainability can be both real and operational.

What This Means for You

If you’re working toward reducing Scope 3 emissions or sourcing more responsibly, this matters. Our products now carry a significantly lower embedded carbon footprint — without compromising quality, performance, or reliability.

A Word to the Industry

We know some still prioritize cost over climate. But we believe in a different approach: where performance and responsibility go hand in hand. The future of glass and refractory production is being shaped now — and we invite you to be part of it.

Want to see it in action?

Talk to our team about how this innovation can support your goals.